From equipment foundation to equipment layout to plant commissioning, our experts take the responsibility for complete plant design and setup. Being an industry-leading galvanizing plant supplier, we make sure you get a great return on your investment while winning the trust of your customers.

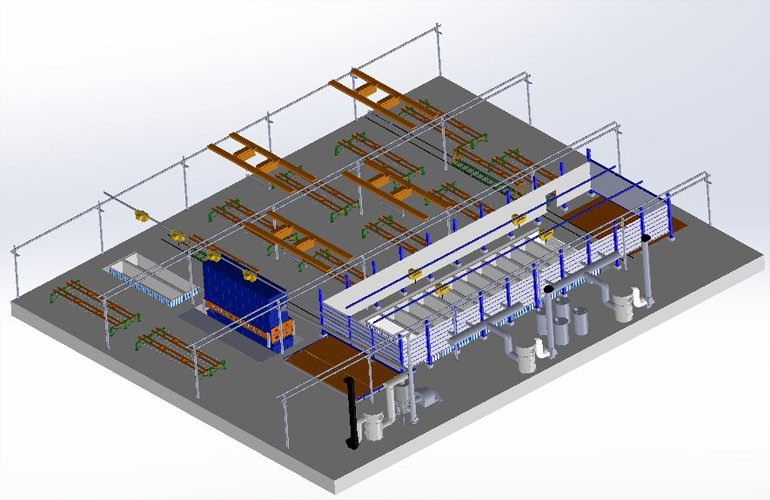

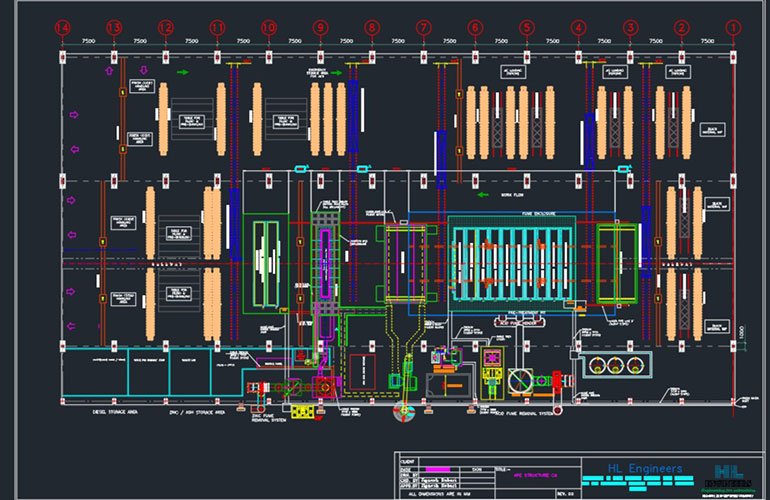

Plant layout is the key element that affects plant performance. It is the plant layout that can make the performance difference to a great extent. Employ our deep specialist knowledge to analyze significant operational flows, power, placement, and resources, finding the balance and deliver a highly efficient plant layout for galvanizing.

Equipment Foundation Design is critical to plant success. It requires deep domain expertise to come up with an optimal civil design. From configurations to sizing of pits to protection to thermal yields, we take care of every detail that adds to the foundation life and cost savings.

For delivering a robust end product to your customers, it is very necessary to have a proper galvanizing process in place. Leveraging our domain knowledge, we tailor an efficient strategy for streamlining the whole galvanizing process and ensuring optimum output.

Installing and commissioning is the last phase of galvanizing plant establishment but the first phase for plant success. Our skilled technicians and project manager will come on your site and act as a connection between your people and resource to get your galvanizing plant functioning smoothly and efficiently for a greater journey ahead.

We recognize the need for cost-effective and quick maintenance. In fact, we design our equipment and plant keeping this aspect mind. Employ our experts for easy yet economical plant and equipment maintenance.